“Weaving the future with green technology, safeguarding the Earth with sustainable fashion.”

Sustainable Development Management

In today’s world, where the global environment is increasingly deteriorating and resources are becoming more strained, the sustainable development of businesses has become a focal point of societal concern. As a globally influential apparel and textile company, we fully understand that, while maintaining business growth, we must also take responsibility for the environment and society. We are committed to using eco-friendly materials and obtaining certifications from internationally authoritative organizations such as Oeko-Tex, Lenzing, and Control Union, ensuring that every product is environmentally friendly during the production process and safe for consumers’ health. With modern production facilities in China, Vietnam, and Cambodia, we minimize resource waste and carbon emissions during production through technological innovation and stringent supply chain management, achieving green management throughout the entire process, from raw materials to garment production. In addition to focusing on environmental protection, we are also committed to providing a good working environment and fair treatment for our employees, actively fulfilling our social responsibilities.

Use of Eco-friendly Materials

The company is committed to adhering to environmental standards in the selection of raw materials to ensure that the negative impact of our products on the environment is minimized during both production and use. All fabrics we use have been certified by internationally recognized organizations such as Oeko-Tex, Lenzing, and Control Union. This means that harmful chemicals are not used during the production process, ensuring the health and safety of consumers. By adopting these certified materials, we not only provide consumers with eco-friendly product options but also contribute to reducing the environmental impact of the textile industry.

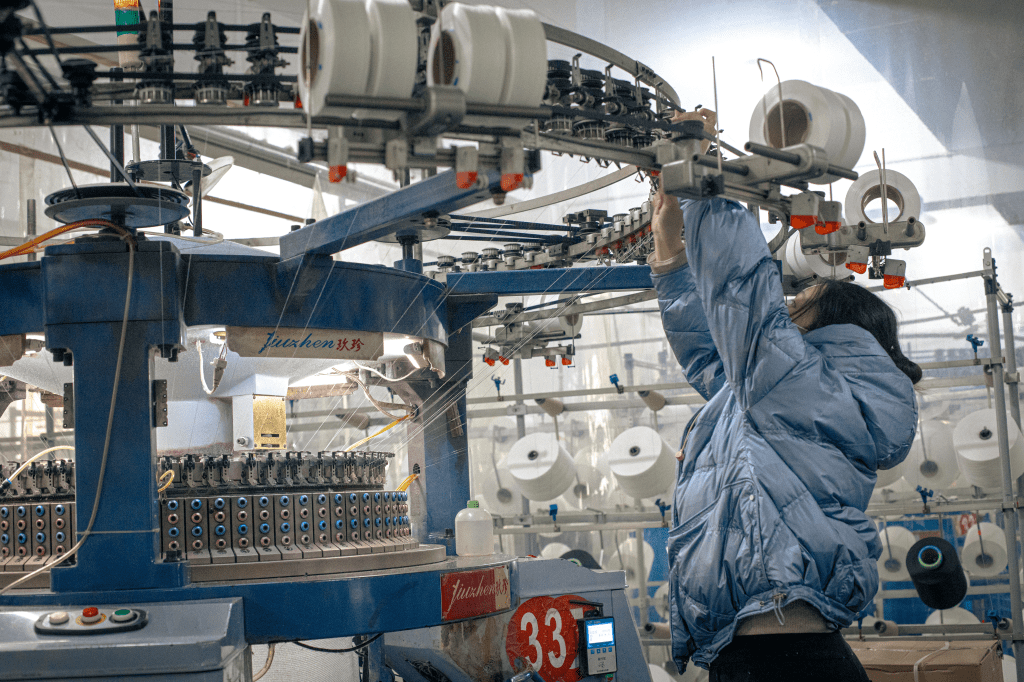

Green Production Processes and Technology

In our factories located in China, Vietnam, and Cambodia, we have introduced advanced production equipment and technologies to achieve higher energy efficiency and resource utilization. By implementing energy-saving equipment, we reduce carbon emissions during production, and through the use of water recycling technology, we lower water consumption. Our goal is to reduce energy consumption, optimize resource management, and minimize environmental impact through waste management systems, actively promoting low-carbon production processes.

Comprehensive Production Chain and Responsibility Management

The company maintains a complete production chain, from raw material procurement to garment manufacturing. This enables us to strictly control environmental standards at every stage of production, ensuring that the entire process, from start to finish, is sustainable. Through responsible management, we reduce waste, optimize supply chain management, and lower carbon emissions, achieving true “green material to green product” management throughout the entire process. This comprehensive chain management not only helps reduce production costs but also enhances our positive impact on environmental protection.

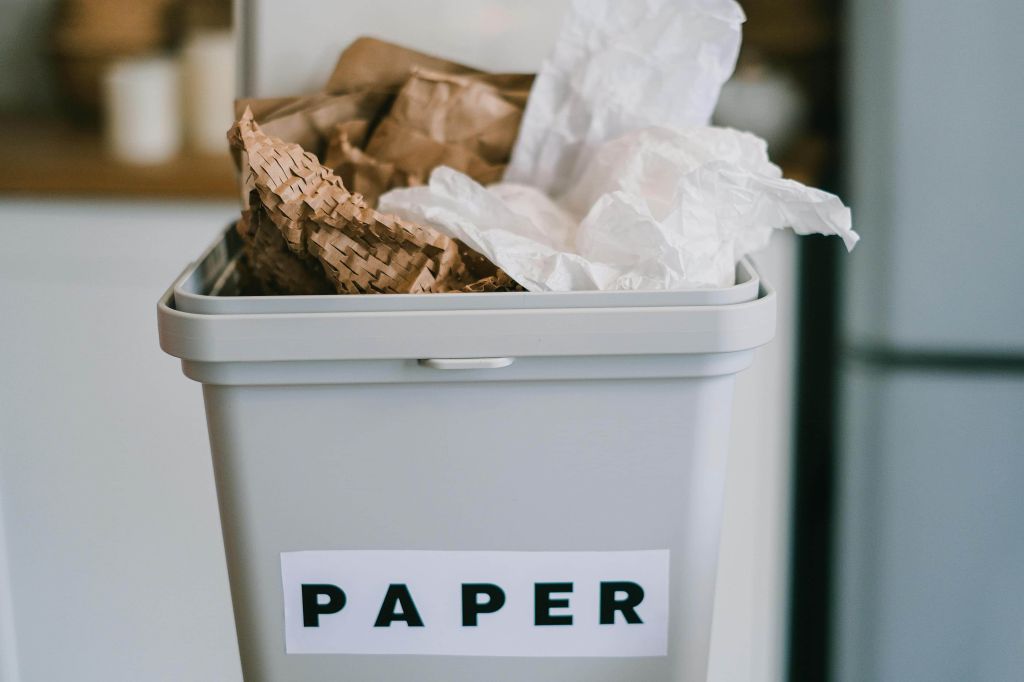

Recycling and Reuse of Textile Waste

We are actively committed to reducing waste in the textile industry and exploring innovative waste management solutions. The company has implemented numerous measures for recycling and reusing scraps and waste generated during the production process, thereby reducing the environmental burden. Additionally, we collaborate with third-party environmental organizations to recycle and reprocess production waste, promoting the “reduce, reuse, and recycle” model. Through these initiatives, we have successfully reduced raw material consumption and contributed to environmental protection.

Social Responsibility and Employee Welfare

Sustainable development encompasses not only environmental responsibility but also social responsibility. As a responsible company, we understand that employees are the cornerstone of our growth. We provide fair wages and a positive working environment, adhering to international labor standards to ensure that employees’ rights are fully protected. We prioritize the health and safety of our staff, regularly improving the workplace and reducing unreasonable working hours to safeguard their physical and mental well-being. Additionally, we actively participate in community support and charitable projects, striving to create positive social change through the company’s influence.

Brand Commitment and Transparency

As a supplier to multiple globally recognized brands, we are committed to incorporating the concept of sustainability into every stage of product design, production, and delivery. Through a transparent supply chain management system, we ensure that our customers are fully aware of our production processes, and that every step complies with environmental standards. Additionally, we pledge to further enhance our environmental standards in material selection and production techniques, reduce our carbon footprint, and increase the use of eco-friendly materials to meet the demand for green products from our customers.

Corporate Green Governance

Hangzhou Yiao Import & Export Co., Ltd. specializes in the research, development, production, and sales of fabrics and fashion products, operating as a fully integrated company with several textile subsidiaries. Headquartered in Guali Town, Xiaoshan District, the company began trading fabrics in March 2007, primarily exporting to the US and European markets. In 2013, it started its own production of knitted fabrics, with core products including Roma cloth, jacquard, and milk silk fabrics. The company has reached $10 million in garment sales to date and currently collaborates with brands such as Calvin Klein, TJMAXX, Karl Lagerfeld, DKNY, New Balance, and Ross.

The company’s rapid growth can be attributed to its high-quality management philosophy, a professional team of experts, and a full industry chain production model—from raw materials to finished garments—providing customers with high-quality, cost-effective services. Scientifically managed and people-oriented, the company is committed to offering a platform for employees to achieve their dreams, with an active focus on training excellent staff. It has cultivated a top-tier management team, including Manager Xing and Manager Jiang from the Garment Department, Manager Guo from the Sample Department, and Manager Cai from the Fabric Department, all of whom have over 20 years of experience in the fabric and garment industry.

The company adheres to standardized operations, stable development, and seeks opportunities in stability and growth through change. It continuously optimizes its projects, enhances management levels, and has gained customer recognition and support through its high-quality products.